Basic Compressor Terms and Definitions

We are compressed air experts – you don’t need to be, once you have us!

For those who wish to get a better understanding of some essential terminology, we have prepared this short compressor glossary:

- Absolute Pressure - The existing gauge pressure plus atmospheric pressure measured from absolute zero.

- Aftercooler - Device that dissipates heat caused by compression after compression is complete. This allows for effective removal of moisture from the compressed air or gas.

- Air Receiver - Tank into which compressed air is delivered and stored. Proper tank size depends on mode of operation. Tank should be sized as recommended by manufacturer. Consult your local Gardner-Denver distributor for assistance.

- Atmospheric Pressure - Pressure at a specific altitude. At sea level, atmospheric pressure is 14.7 PSI.

- Brake Horsepower - The total power input required to compress and deliver a given quantity of air, including losses due to slip and friction as well as mechanical losses.

- Compression - The reduction of a specified volume within a specified cylinder, resulting in an increase in pressure.

- Compression Efficiency - Ratio of the theoretical to the actual work required to compress air. Takes into account slip leakage and frictional losses.

- Compression Ratio - The ratio of the Absolute Discharge Pressure to the Absolute Inlet Pressure.

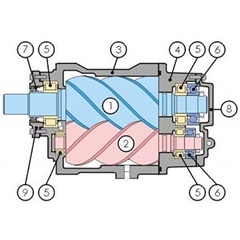

- Compressor - A machine designed for compressing air or gas from an initial pressure to a higher discharge pressure.

- Design Pressure - Maximum continuous operating pressure as designed by the manufacturer. Also referred to as Maximum Working Pressure.

- Design Speed - Maximum continuous operating speed Design Speed - Maximum continuous operating speed of the compressor as designed by the manufacturer.

- Discharge Pressure - Total pressure at the discharge flange of the compressor.

- Discharge Temperature - The temperature at the discharge flange of the compressor.

- Free Air - Air at atmospheric conditions. Be careful with this term because altitude, barometric pressure and temperature will vary. This term may not mean air at identical conditions.

- Inlet Pressure - Total pressure at the inlet flange of the compressor or inlet filter.

- Inlet Temperature - Temperature at the inlet flange of the compressor or inlet filter.

- Load Factor - The ratio of the average actual compressor output to the maximum rated output of the compressor for a defined period of time.

- Moisture Separator - A device designed to collect and remove moisture from the air during the cooling process.

- Speed - Of a compressor is the number of revolutions per minute of the compressor shaft.

- Unloaded Horsepower - The power that is consumed to overcome the frictional losses when operating in an unloaded condition.

- Vacuum - Pressure below atmospheric. It is measured by a differential gauge which shows the difference between that pressure and atmospheric.

- Volumetric Efficiency - The ratio of the actual quantity of air delivered to the displacement of the compressor.

USA (EN)

USA (EN)