Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

USA (EN)

USA (EN)

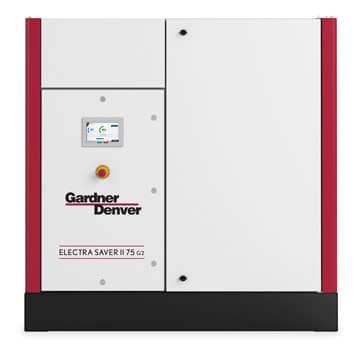

- Rotary Screw Air Compressor

- Electra Saver II G2 Series Air Compressors

How can we help you?