Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

USA (EN)

USA (EN)

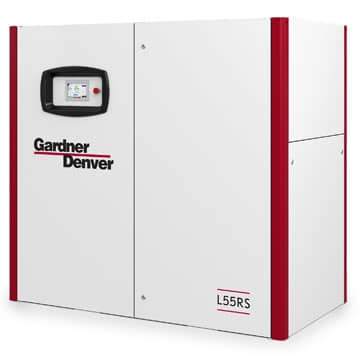

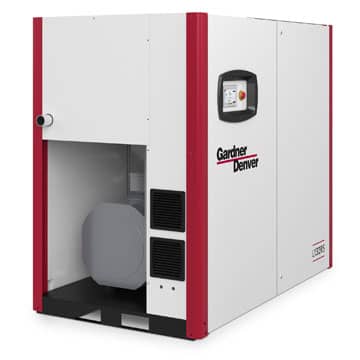

- Rotary Screw Air Compressor

- LRS Series Air Compressors

How can we help you?